Balcony repair and drainage New from the ground up

Heat and UV radiation, rain water, or climate change – all these things usually act on balconies unhindered and can cause a wide range of damage. What exactly causes the damage? And what options are there for the repair? The specialist expertise of painters and varnishers is required here. The experts know: A "new coat" is not enough. A purely cosmetic treatment without prior substrate analysis comes with a high risk of subsequent damage.

Only a sustainable implementation helps to ensure that the components remain intact. The benefits of professional floor coating on a balcony have also convinced planners and end users: Compared with other coatings such as tiles, the coating has a low installation height, a jointless surface and a low installation weight – and offers reliable protection from moisture absorption.

Repair

Testing and assessment

For the extensive testing and assessment of the balcony, the following questions must be clarified in advance by the specialist:

- Is there concrete damage to the balcony floor that has to be repaired?

- Will simple renovation measures be sufficient or does a structural engineer need to be consulted because the damage is too extensive?

- Is moisture damage present? What is the cause?

- Is there an old coating or a tile coating present that may have to be removed?

- What do the connections to the adjacent components look like? Are there leaks?

- What type of substrate is present: Concrete, cement screed, mastic asphalt?

The spectrum of balcony repairs is varied: It ranges from reprofiling of the cantilever plates or balustrades, through to floor coatings and edge joints. The solutions from the Brillux Floortec range are practice-oriented and extensively proven here.

Floortec balcony coatings

Long-lasting protection with a unique design

Whether it's a small area for your free time activities or an extended living room, the balcony is perfect for enjoying a nice break from everyday life outdoors or for finding peace and relaxing with friends over a barbecue. Since balconies, loggias and arcades are generally immediately open to the elements, they are some of the building areas that face the highest degrees of surface exposure.

On the one hand, significant heat build-up due to solar radiation and on the other, rain, snow and frost, cause enormous temperature deviations over the course of the year, sometimes ranging from +90°C to -30°C. These climatic conditions place significantly increased challenges on balcony coatings, in particular in terms of the density required to protect the building, crack-bridging, as well as water drainage to ensure quick drying.

However, mechanical durability is also required in view of the stresses caused by chair and table legs, benches, and heavy flower pots.

And last but not least, the visual appearance of the balcony plays a major role if the balcony is intended as a beautiful place to retreat, to enhance wellbeing. Thanks to the Floortec balcony coatings, there are suitable coating build-ups for the widest range of requirements.

Fast, practical and compliant with standards

The components of Floortec balcony coatings can be flexibly combined, so that the right coating build-up can be found for every requirement. Compared to other coatings, they impress, by creating an almost jointless surface (taking building expansion joints into account) as well as by offering a low installation height and weight.

Many systems that are used to create a new balcony coating consist of a primer, a sealant and then the top coat. While all system build-ups safely protect the structure of the balcony, they differ in terms of speed of build-up, the visual appeal and design freedom, as well as impermeability and durability.

Certified according to DIN 18531 and ETAG 005

The sealing of roofs, balconies, loggias and arcades is regulated in DIN 18531. Part 5 explains the requirements and principles of planning and execution. An essential requirement is that liquid plastics used for waterproofing balconies must have a "European Technical Approval" according to ETAG 005 (Guideline for European Technical Approval).

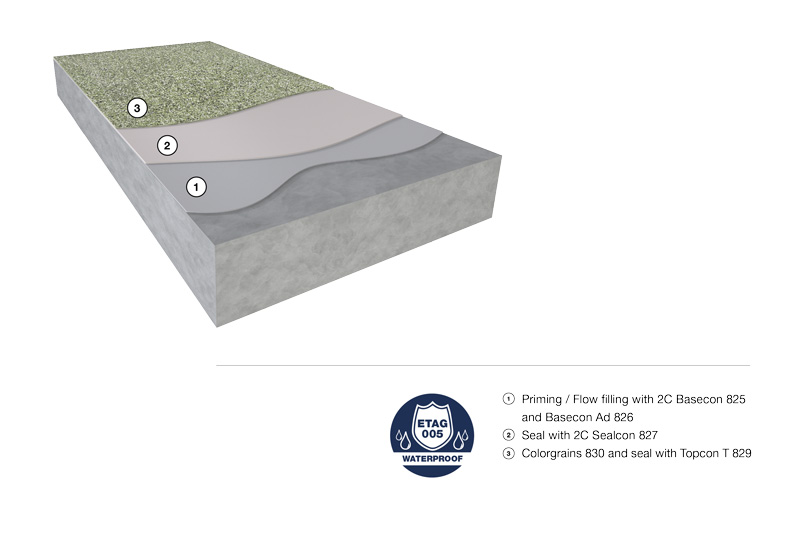

The system build-ups here, which are marked with the "ETAG 005" symbol, meet the high requirements of the guideline in terms of the durability and suitability of waterproofing for use on balconies, loggias and arcades.

Efficient application and maximum protection against leaks

One special feature of Floortec balcony coatings is the approval of the system build-ups using 2K-Sealcon 827, in line with ETAG 005. Sealings can thus be produced in accordance with DIN 18531 – and without additional fleece reinforcement. 2K-Sealcon 827 is applied as liquid plastic, in a material thickness of 2 mm. It dries very quickly and therefore forms and extremely functional seal.

After just a few hours, the coating is already rainproof and can be walked on after a day. Doing away with fleece reinforcement ensures efficient, easy application with notable protection against leaks. Even in joint and detail areas there is a very high level of protection, with high elongation at tear of over 500 %.

The five system build-ups of Floortec balcony coatings

From fast, practical renovation to balcony waterproofing in accordance with ETAG 005/DIN 18531 – thanks to Floortec balcony coatings, Brillux offers the perfect system build-up for a wide range of applications. The individual system build-ups are listed here, with their respective strengths and properties.

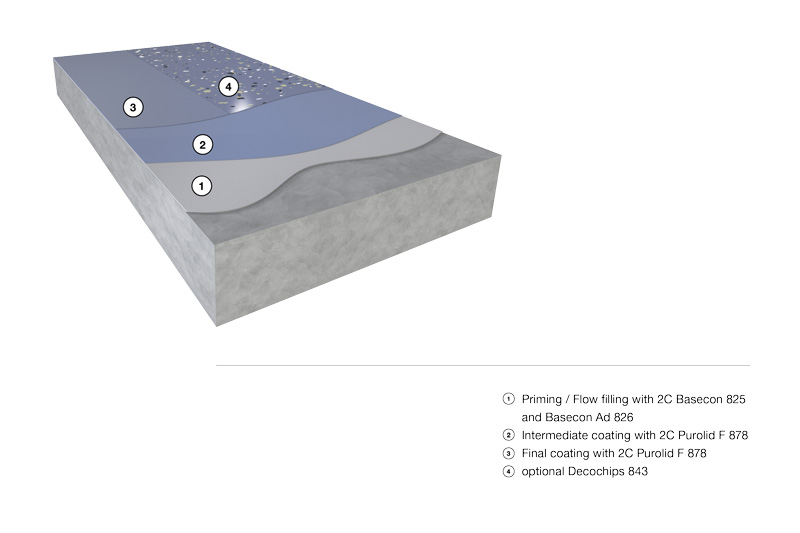

This coating build-up is recommended whenever a fast, practical balcony coating is desired and where no special requirements are placed on leak proofing and crack bridging. The sealer with 2K-Purolid, with pore-filling primer and leveling filer, is suitable for use on mineral balcony slabs. 2K-Purolid can also be used on compatible 2K coatings.

The impressive properties at a glance

- Excellent leveling characteristics

- Very good mechanical resistance

- Film thickness approx. 2 mm

- Time required 2 days (+20°C and 60 % rel. humidity)

- Slip Resistance Class: R9–R11, depending on the selection of the top coat

Versatile surface design

- Decochips 843 with silk matt top seal: 2K-Purolid T 876, silk matt (Slip Resistance Class R10)

- Decochips 843 with silk gloss top seal: 2K-Purolid T 877, silk gloss (Slip Resistance Class R9)

- Transparent top seal with 2K-Purolid T 876, silk matt and Safe Step 841 (Slip Resistance Class R10)

- Transparent top seal with 2K-Purolid T 877, silk gloss and Safe Step 841 (Slip Resistance Class R10)

- Color design accents with 2K-Purolid F 878, silk matt (Slip Resistance Class R9)

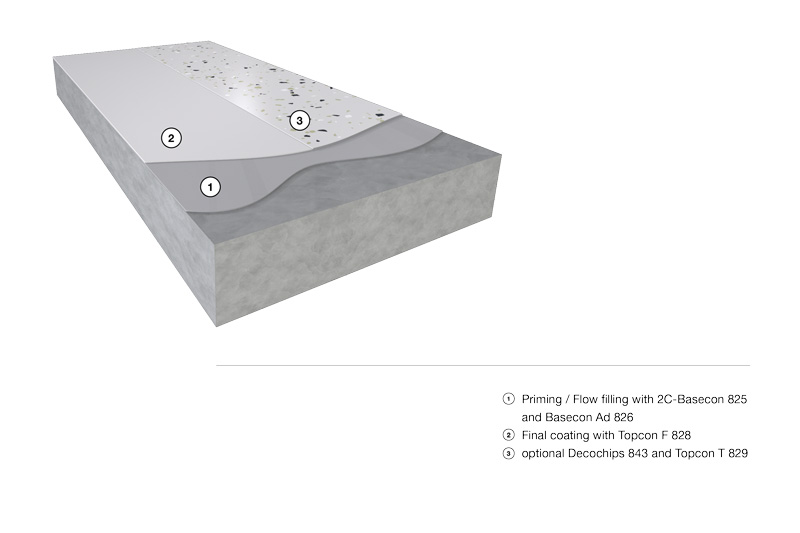

Coating with Topcon F 828 is also a practical solution for balcony sealing, which is suitable for mineral balcony slabs with pore-filling primer and leveling filler. If desired, the surfaces can be individually designed using Decochips 843.

The impressive properties at a glance

- Crack-bridging

- Flexible at low temperatures

- Good mechanical resistance

- Film thickness approx. 2.5 mm

- Time required 1-2 days (+20°C and 60 % rel. humidity)

- Slide-friction coefficient in accordance with DIN 51131 μNM > 0.5 in conjunction with Decochips 843 and slip-resistant surface finish

- Topcon F 828 can also be used directly on compatible 2C coatings, for the purposes of renovation.

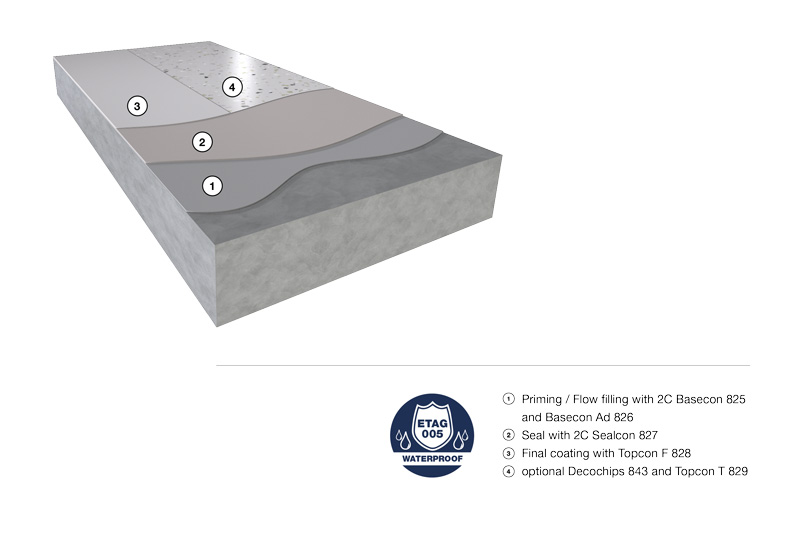

This coating structure with 2K-Sealcon 827 meets the requirements of DIN 18531 for the sealing of balconies, loggias and arcades, in accordance with ETAG 005 approval. 2K-Sealcon 827 is elastic and offers perfect crack bridging and sealing, even without the use of fleece inserts. Topcon F 828 coatings form a perfectly colored finish, with similar elasticity. If desired, the surfaces can be individually designed using Decochips 843.

The impressive properties at a glance

- Balcony sealing in accordance with ETAG 005 using 2K-Sealcon 827

- Can be used without fleece insert

- Very good crack-bridging

- Good mechanical resistance

- Film thickness approx. 4.5 mm

- Time required 2-3 days (+20°C and 60 % rel. humidity)

- Slide-friction coefficient in accordance with DIN 51131 μNM > 0.5 in conjunction with Decochips

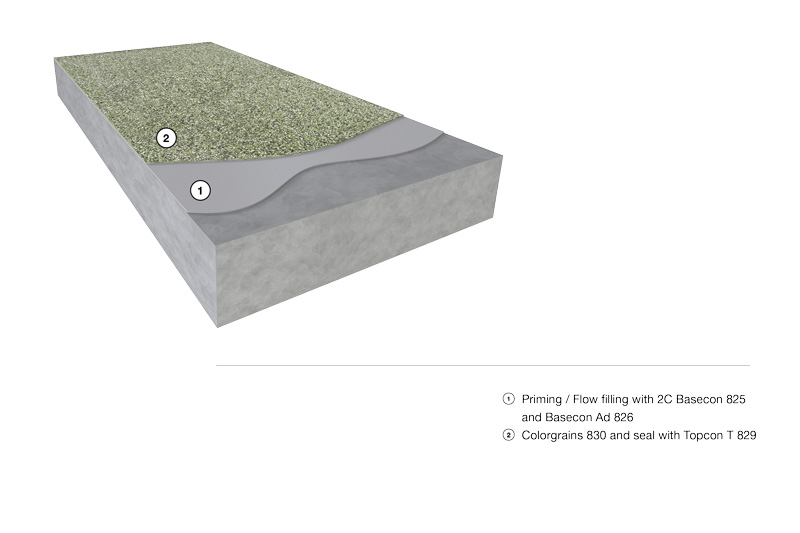

The coating with Colorgrains 830 has the natural look of a flat natural stone and can be combined with a pore-filling primer and leveling filler, both on mineral balcony slabs and on compatible two-component coatings. Quartz is the natural base of Colorgrains 830. Available in various colors, the 0.3–0.8 mm quartzes create a flat look, similar to natural stone.

The impressive properties at a glance

- Crack-bridging

- Flexible at low temperatures

- Good mechanical resistance

- Film thickness approx. 2.8 mm

- Time required 2 days (+20°C and 60% rel. humidity)

- Slip Resistance Class: R12

- Sliding friction coefficient in accordance with DIN 51131 μNM > 0.7

In combination with 2K-Sealcon 827, the coating created with Colorgrains 830 fulfills ETAG 005 approval in accordance with the requirements needed for DIN 18351 in terms of sealing. Processing is carried out efficiently without a fleece insert, as crack bridging is achieved permanently due to the high elasticity of 2K-Sealcon 827.

The impressive properties at a glance

- Balcony sealing in accordance with ETAG 005 using 2K-Sealcon 827

- Can be used without fleece insert

- Very good crack bridging

- Flexible at low temperatures

- Good mechanical resistance

- Time required 3 days (+20°C and 60% rel. humidity)

- Slip Resistance Class: R12

- Sliding friction coefficient in accordance with DIN 51131 μNM > 0.7

Drainage

Coating profiles and gutter system

To prevent rain water from accumulating on the balcony floor, it should be drained off to the drainage system or the edge of the balcony with a slope of at least 1.5 percent.

The necessary drainage systems from Brillux are installed professionally by the painter: a coating profile (BP) made from powder-coated aluminum is first anchored to the balcony floor. After the leveling filling and floor coating, only the drip edge of the profile is visible – a clean solution both visually and technically.

A channel system (BR) can be added as an option. Pre-fabricated corner and drainage elements are also available.