Tools and painting accessories From covering to application

When we say "complete product range", we mean it literally. Because suitable tools and additional materials for the construction site also comprise part of the Brillux product range. In addition to paintbrushes and spraying equipment, we also provide answers to important questions – such as: Which application method should be used when? How can we save valuable time during covering? How does one protect oneself properly while working?

Service

Consultation included

In addition to high-quality tools, the corresponding accessories or spare parts, consultation on system products and recommendations for accessories is also an integral part of our service. It goes without saying that we also ensure the full functionality of the necessary painting accessories.

Application methods

The suitable tools

Rolling, painting, spraying – for first-class results, there is an application method to suit every product.

Paint rollers: The right choice

Which roller? This not only depends on the material to be processed, but also on the desired surface quality. The covering must be coordinated precisely with the coating material with regard to pile height, yarn type, fiber thickness, color retention properties, color coverage, and structure.Brush painting: Not all paintbrushes are the same

But which type of bristle is best for applying paint? Natural bristles achieve the best finish when applying solvent-based paints. Like the particularly strong Chinese pig bristles in the Brillux paintbrushes. Conical, slightly curved and with very good elasticity. Artificial bristles are the unrivaled specialists for applying water-based paints. The tapered polyester bristles retain their shape on contact with water and have a very high resistance to wear and flexural strength.Spraying: Efficient and quick application

High pressure, low pressure, XVLP, Airless, boiler pressure, Airmix/AirCoat: The various spraying systems differ mainly in their spray technology. Here is an overview of the most common versions:|

I. With air for transport and atomization (HD, ND, XVLP) |

II. Without air by means of pure material overpressure (Airless) |

III. Combination of airless technology with air support (Airmix, AirCoat) |

|

The coating material is transported by the air current and broken into paint particles after leaving the nozzle. |

The coating material is conveyed by a pump and pressed through a small nozzle (approx. 0.3–1.5 mm) under pressure (up to 200 bar). After leaving the nozzle, the material is broken up by the enormous outlet speed. |

|

|

In contrast to pure air atomization systems, the airless technology is also suitable for use with emulsions and suitable filler materials. |

This technology blows air in the pressure-reduced (approx. 50–150 bar) material stream of the airless gun, thus supporting the atomization into finer droplets. |

|

|

High pressure (approx. 2–4 bar) creates small droplets, much mist and top surfaces with a small quantity of air (up to approx. 400 l/min). |

|

|

|

This "pure" paint atomization system produces high-quality surfaces. |

||

|

The XVLP technology works with large quantities of air (> 1,800 l/min extra volume) and low pressure (approx. 1 bar low pressure). Outstanding surfaces are achieved with larger droplets, less mist and particularly with the XSpray paints specially designed for the system. |

Occupational safety

Safety and legal obligation

Painting, spraying, grinding, insulating, renovating, paint removal with heat gun, cleaning, or gluing: All of these are the varied tasks of a craftsperson and go hand in hand with stress and hazards. The necessary safety measures are regulated by law.

Occupational safety

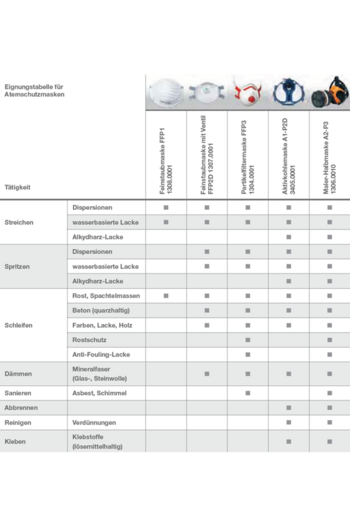

Special filters for better air: If the legally defined limit values for hazardous substance concentrations at the workplace are exceeded, breathing protection must be used. The masks clean the air before hazardous constituents can be inhaled. Different filter material provide protection from the relevant hazardous substances. Duration of use/service life

- Particle filters need to be replaced if the resistance notably increases when breathing.

- Gas filters need to be replaced if there is a noticeable change in odor or taste.

Selecting suitable gloves: Only by being aware of the dangers at the workplace can we protect ourselves adequately. The type and extent of the risks determine the use of the required gloves. All protective gloves must fulfill the standard EN 420, which specifies general requirements for the gloves with regard to, e.g., size and flexibility. Other standards are also relevant for the painter: These are mainly DIN EN 374 81-3 regarding protection from chemicals and DIN EN 388 regarding mechanical risks.

Goggles, hard hat, and shoes make occupational safety complete. Hearing protection: Noise disturbs, impacts negatively or damages. In the workplace, it reduces performance, increases the frequency of errors, and increases the risk of accidents. Head protection: The right hard hat protects the head reliably from mechanical impacts such as falling objects oder bumping one's head. Foot protection: Safety does not have to restrict the worker. This is proven by the sporty safety shoe with steel toe cap and puncture-resistant sole.

Covering and masking

Which masking tape for which surface?

Simply select the surface type from the list on the left. The search result only shows the masking tapes suitable for your application type.

- > Show all

- Acrylic enamel paint

- Aluminum profiles

- Alkyd resin enamel paints

- Connection joints, sealants

- Old coats

- Concrete surfaces

- Construction elements wood

- CV seam welding

- Sealing profiles, PVC, rubber

- DD paint

- Emulsions

- Stainless steel

- Anodized

- Veneers, real wood

- Gypsum plasterboards, primed

- Glass surfaces

- Wood, painted

- Wood, rough sawn

- Ceramics/tiles

- Copper

- Metals

- PVC, weathered (windows/doors)

- Powder-coated profiles

- Parquet sealers

- Stucco moldings

- Zinc surfaces

Masking paper with masking tape (paper)

Masking paper with masking tape (paper) PE-HD foil with masking tape (paper)

PE-HD foil with masking tape (paper) PE-HD foil with masking tape (paper), blue

PE-HD foil with masking tape (paper), blue SK Protection Film, Transparent

SK Protection Film, Transparent

PE-HD foil with masking tape (fabric), light blue

PE-HD foil with masking tape (fabric), light blue Self-adhesive protective foil, blue

Self-adhesive protective foil, blue Masking tape

Masking tape Tesakrepp UV Protective Tape 4438

Tesakrepp UV Protective Tape 4438 Scotch tape 2071

Scotch tape 2071 Render tape, grooved

Render tape, grooved Render tape, smooth

Render tape, smooth Fabric masking tape

Fabric masking tape Universal fabric masking tape

Universal fabric masking tape 3M Super Painter Masking Tape, gold 244

3M Super Painter Masking Tape, gold 244 Tesa Precision Tape, gold 4334

Tesa Precision Tape, gold 4334 Tesa Masking Tape Profi Plus 4306

Tesa Masking Tape Profi Plus 4306 Masking tape neutral

Masking tape neutral Tesakrepp 4341

Tesakrepp 4341 Tesakrepp 4322

Tesakrepp 4322 Tesaflex Fine Line Tape

Tesaflex Fine Line Tape