Coating wooden components Perfect embellishment and permanent protection for wooden components

Wood "lives" and "works". Even when made into wooden components and wood-based materials, it still reacts – particularly in exterior areas – completely naturally to the impacts of wind and weather, such as UV radiation, extreme temperatures, and biological factors, such as fungal decay and insect attack. Appropriate products and know-how are essential when applying coating materials to wooden components to embellish and protect them permanently.

Product assistant

Do you need to coat non-dimensionally accurate, limited dimensionally accurate, or dimensionally accurate wooden components in exterior areas? Or wood and wood-based material in interior areas? Are you looking for a covering, glazing, or colorless wood coating? After the criteria have been selected, the product assistant guides you directly to the right product.

No matches

No suitable product was found for your filter criteria, please widen your search.

No matches

No suitable product was found for your filter criteria, please widen your search.

Wood protection

Constructive wood protection: The most important thing is

No other material is as versatile as wood - but it also has a number of peculiarities to be contended with: As a natural material, wood is extremely challenging. Wood has to be protected from the sun, moisture, and temperature fluctuations. As early as the planning phase, it is important to ensure that wooden components are protected from moisture penetration. Rain and condensation must drain off without obstruction. Because constructive faults cannot be rectified afterwards, even by the best coating system.

- Adequate eaves: The eaves should be dimensioned such that direct weathering is avoided to the greatest possible extent. Wood components should not be used in the splash water zone!

- Protection of end-grain faces: Cut surfaces across the grain (end grain face) are particularly susceptible to moisture absorption and have a high rate of swelling. The end grain face should therefore be protected from direct weathering to the greatest possible extent.

- Drip edges: These serve to drain off the water as quickly as possible.

- Rounded edges: For dimensionally accurate wooden components – e.g. windows – all edges must be rounded to achieve a good edge protection with an adequate layer thickness.

- Avoid contact with the ground!

Chemical wood protection

Chemical wood protection should always be implemented selectively – i.e., only where required due to the type of wood used and the situation on site, and also only where its effect is actually needed: deep in the wood. The impregnation to be used must therefore have a good penetration properties.

Brillux Lignodur Contrabol Aqua 250 and Lignodur Contrabol 550 are ideal for deeply penetrating into the pores of the wood, thus protecting non-lbearing timbers without ground contact in exterior areas as well as windows and exterior doors against blue stain fungus. Its effectiveness was acknowledged in an EU-wide approval procedure for wood preservative.

Physical wood protection

Physical wood protection is used in addition to the constructive measures and chemical protection. In this context, suitable coatings are used, which, on the one hand, keep the impacts of weather away from the wood and, on the other hand, are used for surface design. Flexible protection against algae and fungi In addition to soiling, microorganisms such as algae and fungi are increasingly becoming a problem for exterior surfaces. The unique Protect protection concept from Brillux provides flexible and extensive protection in all color shades and for all substrates – including wood.

Dimensional stability

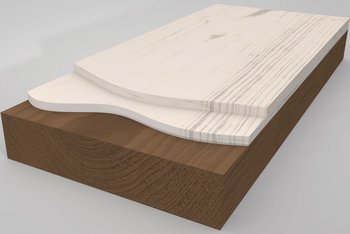

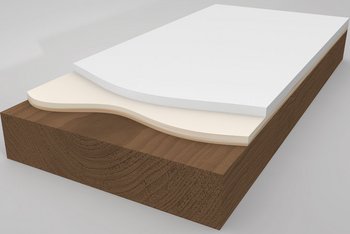

The selection of the correct wood coating is based on the criterion of dimensional stability. This defines how much a wood component changes or is permitted to change its dimensions due to swelling and shrinkage. We differentiate between non-dimensionally accurate, limited dimensionally accurate, and dimensionally accurate wooden components, which all require specific coating build-ups.

Wooden components with a limited range of allowed dimensional changes are considered to have limited dimensional stability. Examples include groove and tongue paneling, garden furniture, framework, roof soffits and ledges, as well as exterior doors, window and door shutters, if they are not already considered to be dimensionally stable.

Reliable care – natural beauty

Natural beauty – oils for the cozy character of wood

Wood is a building material with natural beauty. Thanks to its grain and warm tones, it enhances the environment – both in terms of the mood and sustainability. So that the natural appearance of wooden components remains long-lasting, a reliable protection is now more important than ever. After all, the quality of timber can only be maintained long-term through regular treatment.

Ideal characteristics

The high quality characteristics of Lignodur Hydrodol 240 and Lignodur Xylodol 540 provide a wood treatment and their matt appearance highlights the character of the natural timber. With the two wood oils, it is easy to maintain wood without much effort: You can apply refresher coats at short treatment intervals without much preparation. Both treatment products are excellent alternatives to woodstains. Unlike woodstains, wood oils do not form a film on the wood surface.

Thanks to this characteristic, timber treated with Lignodur wood oils weathers evenly. The coatings do not flake and intense sanding is unnecessary during renovations. With the Lignodur wood oils, Brillux rounds out its full range of products for the professional use of wooden building components.

The benefits of Lignodur Hydrodol 240

- water-based wood oil

- based on natural linseed oil

- for indoors and outdoors

- matt

- low-emission

- excellent penetration behavior

- cures quickly

- pearling effect

- moisture regulating

- EN 71-3, resistant to saliva and perspiration

- AgBB certified

- Container: 750 ml, 3 l, 10 l

The benefits of Lignodur Xylodol 540

- low aromatic wood oil

- based on natural linseed oil

- for outdoors

- matt

- long open time

- excellent penetration behavior

- cures quickly

- pearling effect

- accentuating surface effect

- moisture regulating

- good color stability and weather resistance

- optionally available in Protect quality

- Container: 750 ml, 3 l, 10 l

Renovation with character

Structure-preserving coatings in exterior areas

Wood: A building material with character. In particular, the natural grain and texture make it so popular. This makes it all the more important to maintain this special building material and to protect it from algal or fungal attack, but also from external weather influences.

Lignodur SolvoGuard 885 ensures easy and uncomplicated renovation of dimensionally stable, semi-dimensionally stable and dimensionally unstable wooden components in exterior areas. Even when used over large areas, application is easy and smooth, thanks to the low coating resistance. In addition, the one-pot system reliably prevents the striking through of wood constituents. This means that no product changes are necessary during the renovation.

Smooth coats for naturally beautiful wood

Whether it's on wooden paneling, facades, fences, roof soffits, balconies, windows or exterior doors: Lignodur SolvoGuard 885 optimally protects various wooden components from the effects of weather thanks to its good flow properties and high stability. Since the coating protects against fungal attack, the value of the wood remains for a long time. The texture-preserving coating with a silk matt surface has a naturally beautiful effect and thus emphasizes the unique character of the wood.

What's so special about it is that the wood paint, based on long-oiled alkyd resin, is available in a variety of color shades and translucent color shades via the Color System and enables uniform surface results on unevenly weathered wooden components depending on the substrate and preference.

The benefits of Lignodur SolvoGuard 885 at a glance:

- Based on long-oil alkyd resin

- Available in opaque and translucent color shades

- Film protection from the factory

- For exterior use only

- Silk matt

- Drip-inhibited for safe overhead work

- Easy to apply, even when used over large areas

- One-pot system

- Moisture regulating

- Prevents wood constituents from striking through

- Block-resistant

- Optionally available in Protect quality

Water-based woodstain

The best long-term protection for wooden components

Whether it's on wooden paneling, facade claddings, fences, roof soffits, balconies, windows or doors: Wood coatings must withstand changing weather conditions, especially in exterior areas. With their robust properties, they ensure maximum functionality and support a long-lasting, attractive appearance.

Lignodur TopGuard 280 is primarily suitable for outdoor use on dimensionally stable, partially dimensionally stable and dimensionally unstable wooden components – but can also be used in interior areas due to low odor levels. The premium woodstain gives hardwoods and coniferous woods a high-quality protective layer.

Easy application, lasting protection, attractive appearance

It combines the best of both worlds with modern hybrid technology. Thanks to the combination of alkyd and acrylate bonding agents, it enables easy application with a long open time and at the same time offers high weather resistance and color stability.

Lignodur TopGuard 280 also dries faster than conventional alkyd resin woodstains, ensuring short downtimes. At the same time, however, it impresses with its estimated color shade firing of the wood.

See the benefits of Lignodur TopGuard 280 Premium Woodstain for yourself:

- Water-based

- Modern hybrid bonding technology

- Especially suitable for exterior use, but can also be used indoors

- Silk gloss

- Long open time

- Slightly drip inhibted

- Fast-drying

- Good penetration properties

- Refreshing surface effect for visually appealing, intense real wood color shades

- High color stability

- Highly diffusible

- Optionally available for outdoor use in Protect quality

Grenodecor

What's inside, matters

Most people spend a lot of their time indoors. That's why it's all the more important to make them decorative. Health in your home is just as important. For this purpose, the products used must be low-pollutant and low-emission and have low odor pollution.

Like Lignodur Grenodecor 236. The water-based wood glaze offers great decorative quality and creates a relaxed, feel-good atmosphere. The matt gloss of the coating emphasizes the natural wood look.

Woodstain for well-being and a natural look

Whether it's on doors, ceiling panels or cladding, Lignodur Grenodecor 236 is particularly suited to all interior wooden components. Another plus? The decorative glaze can also be used with the clearest conscience from a health perspective. For example, it is completely safe in the event of saliva and perspiration, in accordance with EN 71-3, certified with the Blue Angel and AgBB tested.

See the advantages of Lignodur Grenodecor 236 Wood Gloss for yourself:

- Water-based

- Low-emission

- Acrylate base

- For interior and exterior use

- Matt

- One-pot system

- Easy application, thanks to low resistance when brushing on

- Good penetration properties

- Discreet surface effect

- Fast-drying

- Highly diffusible

Aesthetics and function

Lignodur VarioGuard 618 and Lignodur VarioGuard 620

Wood is an organic, renewable material. But continuous exposure to weather requires a special, long-lasting coating to care for it. Are you looking to achieve the best visual result when designing both interior and exterior areas, while still ensuring appropriate, all-round protection for wooden acades and other wood components.

Then don't make any compromises. Our Lignodur VarioGuard 618 and Lignodur VarioGuard 620 are specially designed to protect wooden surfaces. For those who prefer a matter, more natural wood effect, then Lignodur VarioGuard 618 is the right choice. Alternatively, our Lignodur VarioGuard 620 ensures a great, silk gloss wood effect – and of course, both woodstains are aromatics-free.

Practical application

Benefit from particularly good wood penetration and easy application. Both products are drip-inhibited for safe overhead work and offer easy application thanks to the appropriate viscosity. Both woodstains are available in eleven standard colors. If desired, the finish can be individually tailored using the Brillux Color System, offering over 60 color shades.

A fine selection in both matt and silk gloss

| Lignodur VarioGuard 618 | Lignodur VarioGuard 620 | |

|---|---|---|

| Matt, aromatics-free alkyd resin enamel paint | Silk gloss, aromatics-free alkyd resin enamel paint | |

| Retains the wood's natural appearance | Ideally suited for surfaces exposed to tough weather conditions due to high gloss | |

| Thanks to appropriate viscosity, it's easy to apply and spread out | Thanks to appropriate viscosity, it's easy to apply and spread out | |

| Particularly good penetration into wood | Particularly good penetration into wood | |

| Optional Protect properties | Optional Protect properties | |

| Available in 750 ml, 3 and 10 liters | Available in 750 ml, 3 and 5 liters |

Metallic

Vintage look thanks to metallic color shades

Age wood formworks, wooden paneling, fences or garden houses in a vintage look: That’s currently on trend. Brillux is responding to this with an extended color spectrum for the Lignodur VarioGuard Tix 510. Eight new metallic woodstain color shades can skillfully age wooden surfaces.

On untreated wood, UV radiation gradually breaks down the wood component lignin. The result: The wood grays and, depending on the wood type, gradually forms a silvery metallic patina. This natural look is currently extremely popular, but is usually extremely uneven due to the design characteristics and changing weathering. The metallic color shades of Lignodur VarioGuard Tix 510 can imitate the appealing look of naturally weathered old wood with even results.

The deep penetrating alkyd resin woodstain can be used on all interior and exterior hardwoods and coniferous woods and, thanks to the high solids content, is also suitable for weather-resistant coatings on wooden components with no or limited dimensional stability. Thanks to the thixotropic modification, it also offers extremely easy and drip-free application overhead.

In addition to the aesthetic results and protection from wind and weather, the Lignodur VarioGuard Tix 510 can be optionally equipped with Protect to offer protection from algal and fungal infestation. This means that the user has a choice and only uses biocides where required due to the object parameters.

Imitation of natural weathering

In direct comparison, we can see how the uneven natural graying (left) can be imitated evenly with Lignodur VarioGuard Tix 510 (right).

Brightening technique

Brillux practical tips for professionals

The brightening technique is used where visual harmonization between dark wood components and other surfaces is required – for example new windows or doors. The desired effect is achieved with a coordinated combination of covering prime coating and glazing finish.

Isolation of wood constituents

The most important thing is

The situation: White paneling has just been painted, and it suddenly has a brownish shimmer or exhibits ugly yellow flecks. The cause: Wood is a demanding material made up largely of organic components, but also contains certain quantities of wood constituents. These substances are water-soluble and can be transported from one layer to another and eventually reach the surface when water-based coating materials are used. The solution: Whereas, with conventional water-based prime coats, a large fraction of the wood constituents are transported to the coating surface, Isoprimer 243 or Hydro-PU-XSpray Isoprimer 2243 effectively prevents such penetration. The recipe for success lies in the cationic isolating effect. The special formula and a slightly acidic pH value achieve an outstanding barrier effect. Wood constituents therefore cannot penetrate the coating film.

Standards and regulations

Important standards and regulations for wood coating

There are a number of standards and regulations for first coats and renovation coatings on wood components in exterior areas. They provide information on special properties of wood substrates and the effect of different coating materials, list testing methods, provide application information, and define what measures should be taken when. In addition to these standards and regulations, the data sheets from the manufacturer provide detailed insight into the application and provide details on the relevant product.

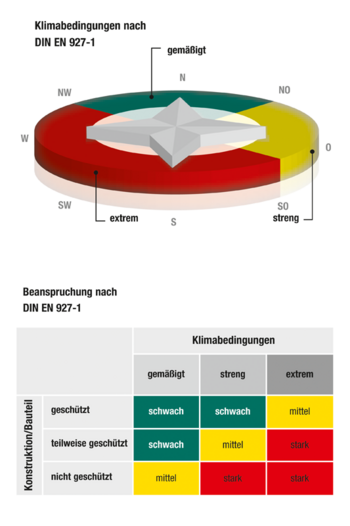

Leaflet No. 18 (Coatings on wood and wood-based materials in exterior areas) provides extensive information on the material wood, substrate tests, and coating build-ups – both for dimensionally stable wood components, components with limited dimensional stability, and non-dimensionally stable wooden components. The technical regulations for coating all components made of wood and wood-based materials in building construction are taken into account and explained. This leaflet also provides information on the stress conditions for coatings. Leaflet No. 18 refers to DIN EN 927-1 (Coating materials and coating systems for wood in exterior areas) in this regard. The stress conditions are not only dependent on the climate conditions at the site, but also on constructive protection via structural measures, e.g. through canopies or reveals (see diagram on the right).

In part C of the VOB (Construction Tendering and Contract Regulations), the basic principles for the professional approach to work and material selection for painters and painting work are stipulated in DIN 18363. Part C also applies to contracts in accordance with BGB (German Civil Code) and does not require separate agreement.

In the standard DIN EN 350-2 (Durability of wood and wood-based products - Natural durability of solid wood), the types of wood are divided into classes according to their resistance to wood-destroying fungi, microorganisms, and insects.

Defines preventative chemical wood protection and its usage conditions. For coatings, paragraph 12 (non-bearing, dimensionally stable wood, protection of windows and exterior doors) is primarily relevant in this context.