Proper coating build-up The important thing is

Professionals can identify a good product just by using it. Their expert eyes can see immediately whether the surface appearance is developing uniformly and whether the coating will withstand mechanical stress.

Metallic substrates

Stressable, but susceptible to corrosion

Metal is a versatile, highly stressable material. This is why it is used in many different forms in construction. But although metal components have outstanding static properties: only lasting protection from corrosion guarantees maximum value preservation and optimal durability. Ferrous metal (F-metal) and non-ferrous metal (NF metal, e.g. zinc) require different coating build-ups. First of all, it is important to check what metal the surface is made of:

- Magnet test: Raw iron and crude steel are magnetic, but so are galvanized F-metals.

- Spangles on the surfaces indicate galvanized metal. In case of doubt, test with a cent coin: rubbing over the metal with the coin will leave black streaks on zinc dust coatings.

Also:

- Inspect raw metals for processing residues, soiling or corrosion.

- Test whether the substrate is free from grease and oils, e.g. with a wetting test with water or by applying absorbent paper.

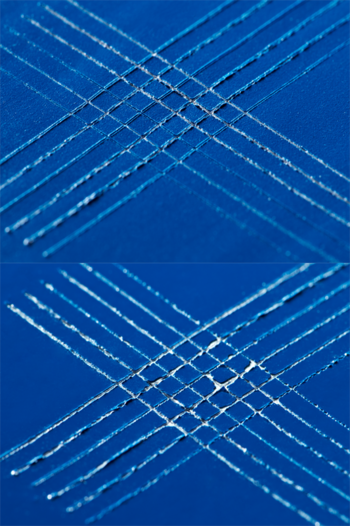

- Check the load-bearing capacity of the prime coat or old coating – with a scratch test and cross-hatch adhesion test, supplemented with an adhesive tape test where applicable.

F-metals

F-metals must have corrosion protection. Otherwise they would quickly oxidize and eventually lose stability. Reliable, lasting and high-quality corrosion protection therefore starts with careful pretreatment of the substrate. DIN EN ISO 12944 defines the criteria for creating a coating that is as impermeable as possible. It stipulates that the required minimum thickness depends on two factors: the corrosiveness category, i.e. the protection duration to be achieved, and the bonding agent of the prime coat. Multi-Primer 227 and MP Thick Film 229 have proven effective as a corrosion protection system for iron and steel components.

NF-metals

Zinc coatings protect steel and iron effectively from corrosion – but are quickly attacked by aggressive air pollutants. Proper coating helps in such cases. The most important quality criteria here: an optimal adhesion bond with the zinc surface. This is already significantly affected by the bonding agent type. Our recommendation: Multi-Primer 227. The product based on mixed polymer resin guarantees minimum embrittlement and therefore offers optimal long-term protection. On zinc-coated iron parts with old coatings, the adhesion properties are particularly critical. Therefore, test them beforehand. Because: Old coatings with low levels of adhesion on zinc coatings tend to flake.Old coatings

Check and pretreat carefully

It is important to inspect the coatings carefully before application. Due to the relatively low solid content in water-based paints, substrate roughness is tendentially less well leveled than with solvent-based alkyd resin enamel paints. The choice of the abrasive also has a significant impact on the quality of the surface. To prevent normal sandpaper from clogging: Treat acrylate surfaces with a paper that contains dust-repelling materials in the size coat. With a nonwoven abrasivel, on the other hand, the gaps are sufficiently large and therefore do not clog as easily. Our professional tips for checking the substrate:

- Check the load-bearing capacity of the old coating with a scratch test, cross-hatch adhesion test, and adhesive tape test

- Determine the type of coating using cellulose thinner: If the old coating dissolves readily, it is a physically drying system, e.g. a polymer resin or emulsion coating. No or minor dissolution indicates a chemically hardening system, e.g. based on alkyd resin enamel paint.

- Greases, oils and separating agents can be verified by a wetting test with water – and removed with Universal Cleaner 1032 where necessary. Then lightly sand the surface.

Coil coating

Problematic substrates Factory-made coatings

Be cautious when using a factory-made prime coat or a coil coating. Conventional substrate testing methods such as scratch tests and cross-hatch adhesion tests may initially provide good adhesion data. Flaking may nevertheless occur after coating. The new coating should therefore always be matched to the existing old coating. 2K-EP Varioprimer is particularly suitable as a prime coat for coil coatings, powder coatings, and two-component coatings. In individual cases, the suitability must be checked on-site with a test coat.

Hard PVC

Challenging: Plastics

Window and door frames, but also facade and balcony paneling, are often made of hard PVC. This can be coated for design reasons: to improve the appearance of components that have been weathered, for example. Or to create a different color design. However, the coating system must be specifically suitable for use on plastics. Silicones or waxes used as mold separating agents during plastics manufacturing also make adding a subsequent coating even more difficult. Our recommendation for a particularly durable prime coat: 2K-EP Varioprimer.

Our professional tips for checking the substrate:

- Are the components soiled? Ideally, clean the surfaces thoroughly beforehand.

- A wetting test with water shows whether the components are free from greases, oils, and separating agents. Remove greasy soiling with diluted ammonia and wetting agents or Universal Cleaner 1032. For light surface sanding, it is advisable to use the nonwoven abrasive sponge 1189.

- Weathering residues can be identified by rubbing with the hand – sand if necessary and clean with a damp cloth.

- Check the load-bearing capacity with a scratch test, cross-cut test, and perform an adhesive tape test where applicable. Remove the coating if necessary.

Primer Selection Guide

No matches

No suitable product was found for your filter criteria, please widen your search.